The generator is responsible for converting the kinetic energy of the turbine rotation into electrical energy. We can provide both low and high voltage generators. Usually, when the power of a single generator is less than 3000KW, we use low-voltage generators, and when it is higher than 3000KW, we use high-voltage generators.

Contact usThe output voltage of the low-voltage generator is below 1000V. Can be customized according to the needs of users. Low voltage generator transmission cost is high, suitable for small factories, residential backup power and other electricity scenarios without long-distance transmission.

The output voltage of the high-voltage generator is more than 1000V, and the commonly used high-voltage generator voltage specifications are 6300V, 10500V, 13800V, 15000V and so on. It is suitable for high-power long-distance transmission scenarios and can reduce transmission cable cost and transmission loss.

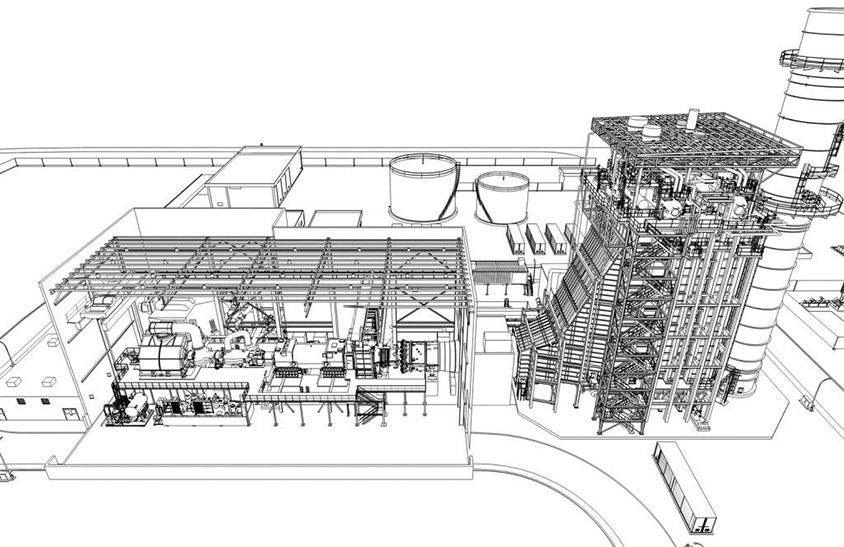

FangKuai Combined Heat and Power Projects Integration Supplier offers customized power systems to meet a wide range of customer needs and applications, including:

Improve performance

Single bearing design

Advanced sealing features

High-efficiency last-stage blades

Advanced blading

In order to ensure the best solution for each situation, we first analyze the current situation and the modifications required. We determine which components need to be replaced, which technologies are most appropriate, and how to most easily integrate new systems into existing plant architectures.

We are a specialist generator service provider with a regional service team to support your local generator maintenance needs. Our support includes industrial generator and large generator expertise. Our operating network consists of a world-class network of factories, service centers, suppliers, and warehouse logistics and inventory centers.

Get Free Solution

We provide medium and long-term solutions to the problems of biomass waste, transforming waste into energy at no environmental cost and making it economically viable and at the same time compatible with the international environmental regulations and standards

Get More Product Information For Free